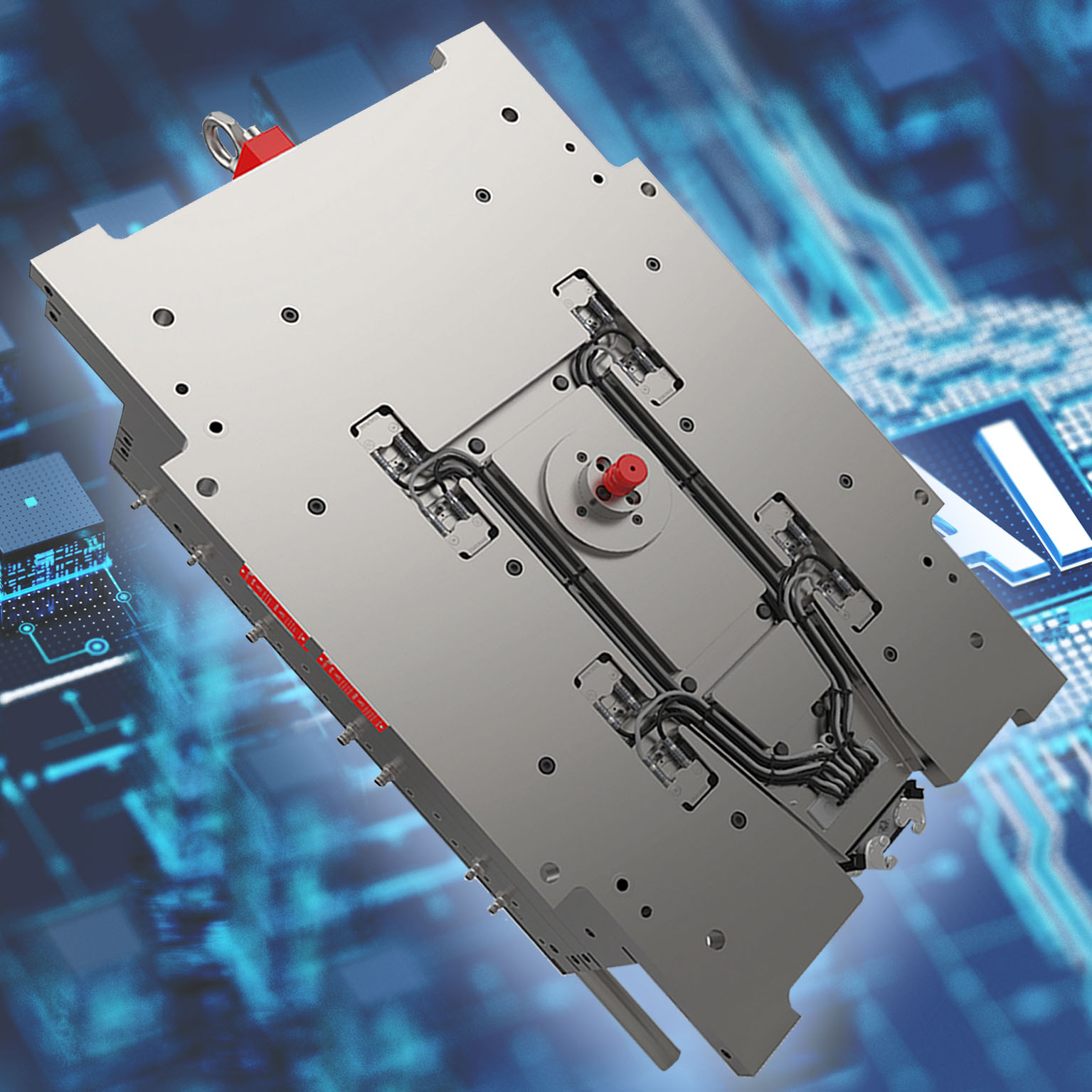

The patent-pending SMARTshot I cold runner measurement and control concept incorporating servoelectrically actuated nozzle needles, currently under development by LSR mold specialist Elmet, is an intelligent variant of the SMARTshot E system. Once deployed in a practical setting, entirely automatic startup will be possible as will controlled family molds with cavities of differing volumes that do not require additional sensor systems. This will enable cascaded injection processes with time-delayed opening and closing movements as well as injection processes with partially open needles for simultaneously filling cavities with different volumetric flow rates per nozzle. Elmet will give an update of this new concept at LSR 2025 (16 to 19 June 2025 in Irvine, California).