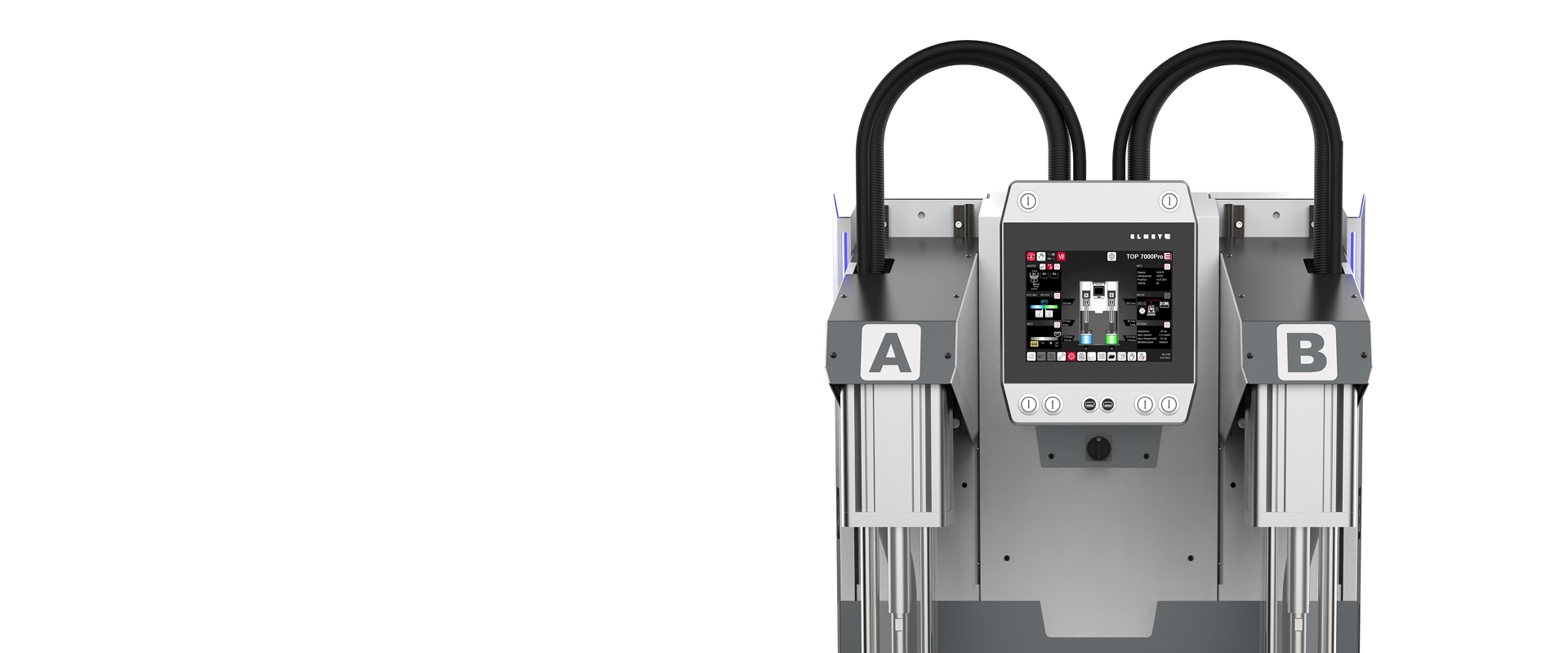

Unmatched range of features, uncompromising precision, and absolute process reliability: The TOP 7000 Pro is our highest-performing dosing system and sets new standards in the high-end segment. Developed for the highest demands, it processes both 200 liter and 20 liter containers with maximum efficiency and a constant mixing ratio.

Featuring state-of-the-art software, intuitive operator control, and practical details such as integrated transport wheels, the system combines top-tier technology with maximum user convenience. Our TOP 7000 Pro is the number one choice where highest component quality and production reliability are crucial.

High performance

Stable & precise

Cost effectiveness

Energy efficiency

Versatile in use

Safety

User friendly

* measured with silicone oil at ẏ=10 1/s η = 2.7 Pas (A+B components) | ** ẏ=10/s | *** ẏ=0.2/s

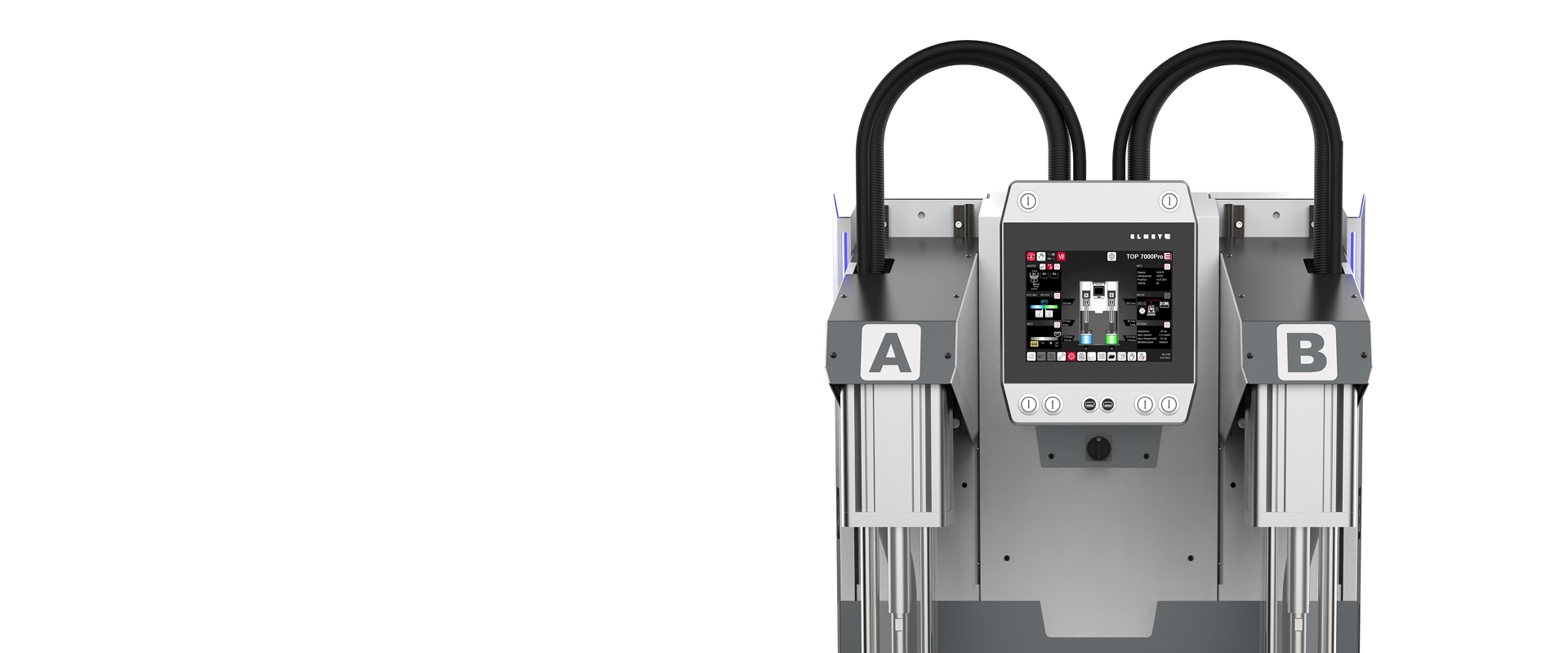

Safety is ELMET's top priority.

With the TOP 7000 Pro, we are not only setting new standards in terms of energy efficiency, performance, and process stability, but also in the area of machine safety. Our systems meet the highest standards and have been successfully tested and inspected by TÜV SÜD.

This means we can offer you the demonstrably safest dosing system in the market.

Shore-Mix

LSR Select

Barcode drum detection

Drum lifting device

Customized paint work

Premium Connectivity

Simplex

(1 dosing system on 2 injection molding machines)

Tandem

(2 dosing systems in alternating operation)

Try out our dosing systems free of charge and without obligations

Save energy & reduce CO2 emissions

Forget the myth that pneumatic dosing systems always consume more energy than electric ones. ELMET technology proves the opposite – and sets new standards:

Up to 50% less energy consumption compared to purely electrically operated pumps – that means:

Lower CO2 emissions

Lower operating costs

Greater sustainability