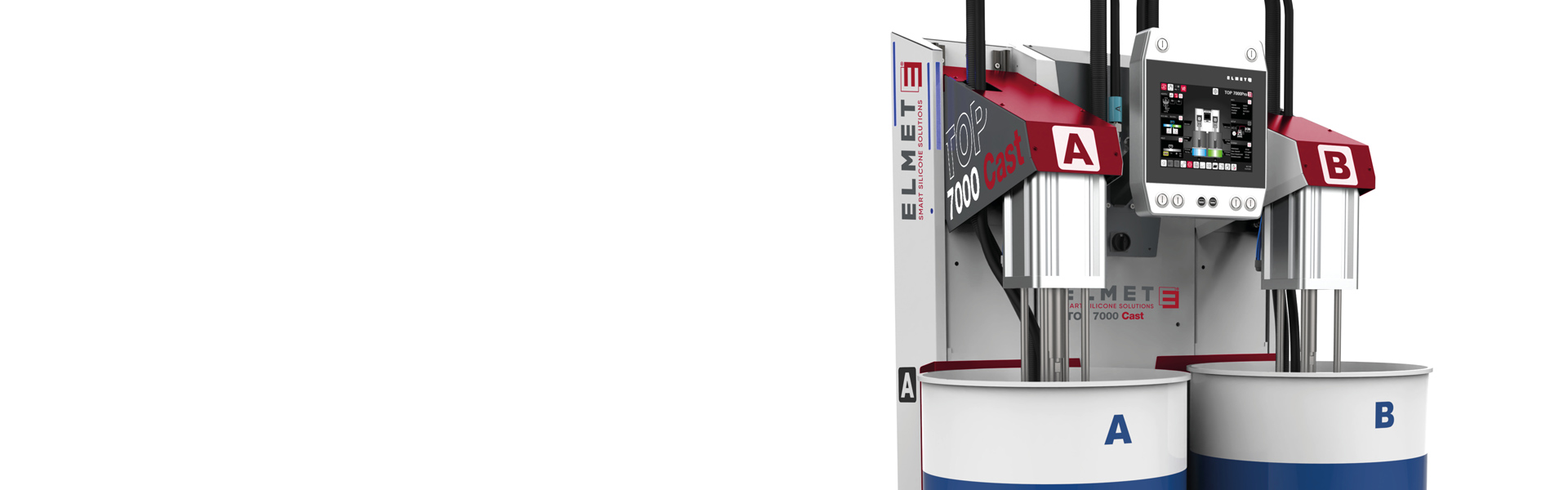

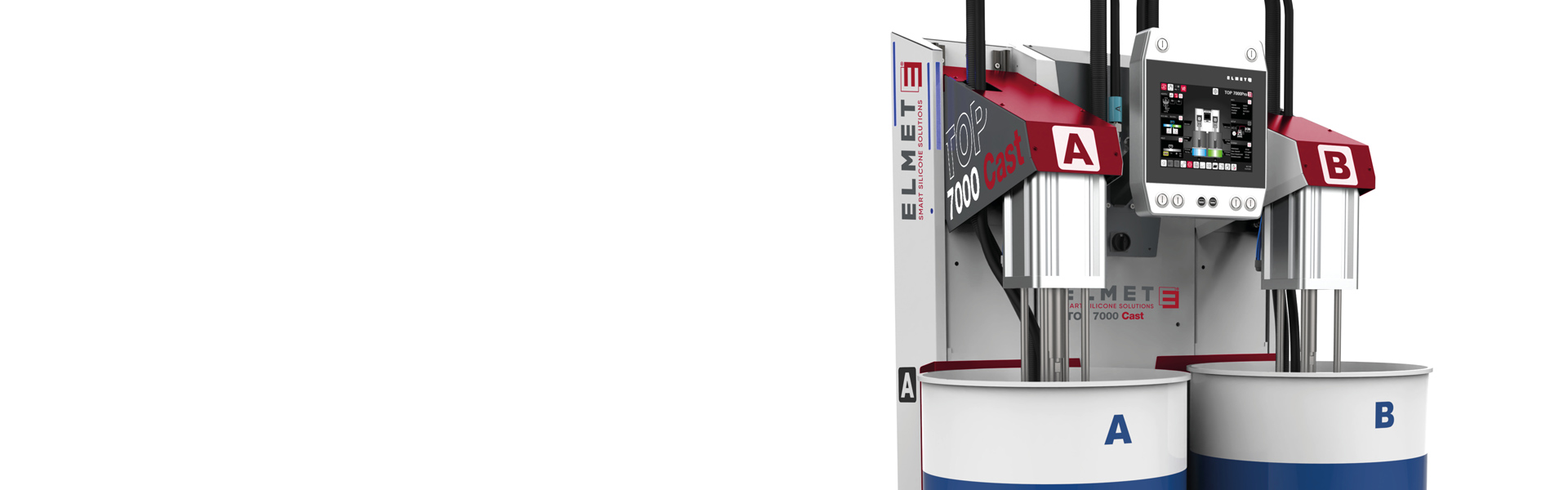

TOP 7000 Cast

Constant volume flow. Stable mixing ratio. Reproducible results.

Constant volume flow. Stable mixing ratio. Reproducible results.

The TOP 7000 Cast dosing system for casting, coating, and manual molding applications is based on the TOP 7000 Pro and was developed specifically for casting applications.

Result:

Maximum process stability, high material utilization, and reproducible results – perfectly adaptable to the material viscosity.

Areas of application:

Direct filling of insulators (HVI) and other electronic technology components, manual molding with and without dispensing guns, medical applications (manifolds, LSR liners, cushions), fabric and paper release coatings, and cable coatings.

The TOP 7000 Cast maintains consistent mixing ratios and a stable volume flow, even when viscosity and fillers vary greatly. Ramp profiles, freely definable shutdown criteria, and QR code recipe management allow the system to be quickly adapted to changing processes and small batches.

Fully automatic drum change and user-friendly software reduce operating costs. The self-learning control system automatically adapts to the conveying behavior of the material and increases process reliability—even with highly filled or abrasive materials.

With a standby power consumption of only around 50 Wh, minimal maintenance requirements, and a wide range of processable viscosities, the TOP 7000 Cast sets a new standard in efficiency, usability, and process reliability.

30 years of ELMET – 30-month warranty

ELMET dosing systems purchased in the anniversary year 2026 are automatically covered by a 30-month warranty.

Valid for direct purchases from ELMET. Worldwide, except Asia. The general warranty conditions for ELMET dosing systems apply.

Direct filling / casting

Insulators (HVI casting)

Typical application in high- and medium-voltage ranges, high requirements for filling quality and process consistency.

Manual molding

With or without a dispensing gun – the system supports both options.

Medical products with high requirements for precision, material homogeneity, and reproducible filling processes.

Coating processes

Uniform, controlled material application required. Advantage due to continuous, stable volume flow.

Cable coating

Coatings or protective layers; requires controlled and stable material flow as well as high viscosity tolerance.

Performance & process stability

Flow rate > 5 l/min (depending on viscosity)

Max. pump pressure 280 bar – enables stable and highly dynamic delivery even with highly viscous and abrasive materials

Precision: 2.0 µl/imp (512,000 imp/L)

Stable, continuous conveying

Precise mixing ratio – high mold filling quality, reproducible components

Material & energy efficiency

Material utilization up to 99.8% – real cost advantage, hardly any residual material

Low power consumption: approx. 50 Wh in standby mode, 150 to 400 Wh during operation

No idle losses, no pressure loss

Operation & automation

Fully automatic drum change from the drum edge

200 liter/55 gallons drum pair change < 5 minutes – fast restart

Fully automatic venting – reduces operating errors and waste

Over 20 software operating languages as standard

Intuitive user interface

Intelligent process control

Volume flow control via up to 5 ramp profiles with shutdown criteria

Integrated shutdown criteria (time, volume, filling pressure, external start/stop signal)

Self-learning control, automatically adapts to material viscosity

Material flexibility

0.001 – 3,000 Pas

Whether low or high viscosity – the system reliably conveys everything

Optional wear-resistant design – suitable for highly filled, abrasive materials

Additives & recipe management

Control of up to 6 additives, high resolution (10,240,000 pulses/L)

Recipe management via QR code:

Load production and process parameters in seconds

Error-free, digital recipe management

Security & compliance

Complies with EN ISO 13849-1 – the highest safety standard on the market.

CE, RoHS, and UL compliant.

Permanently mounted material hose connection – no strain on components due to material hoses.

Intuitive and extremely easy to use.

Safety is ELMET's top priority.

With our dosing systems, we not only set standards in terms of energy efficiency, performance, and process stability, but also in the area of machine safety. Our systems meet the highest requirements and have been successfully tested by TÜV SÜD.

This means we offer you the proven safest dosing system on the market.

up to 6 additives

QR code recipe management

Abrasive kit

for highly filled/abrasive materials

Customized paint work

Drum lifter

Tandem

2 dosing systems in alternating operation

Premium Connectivity

SMARTsupport Hub

Maximum system availability through smart remote support

Fix-Mix

Freely selectable mixing ratio

The TOP 7000 Cast is a dosing system specially developed for casting, coating, and manual molding processes that works without intermediate systems (e.g., injection molding machines). Direct filling of molds or casting of material onto various materials/components.

The system ensures a constant volume flow and a stable mixing ratio – even with highly fluctuating viscosities or highly filled materials. In addition, Elmet systems excel with fully automatic drum changeover from the drum edge, sophisticated user-friendly software, and self-learning control, which is essential for reproducible component quality even under changing process conditions.

Direct filling/casting (e.g., high-voltage insulators, cable joints), manual molding (including medical manifolds, LSR liners), various coating processes (e.g., cable coating, fabric coating)

Ramp profiles, freely definable shutdown criteria, and QR code-based recipe management allow production parameters to be loaded quickly, clearly, and without errors. A QR code scan automatically sets all production parameters (profile settings – volume flow, material quantity, additives, etc.) for the subsequent process. This enables short changeover times and reliable production even with frequently changing recipes.

The processable viscosity range extends from 0.001 to 3,000 Pas. The system is suitable for standard, flame-retardant, oil-resistant, HVI, and medical materials. A wear-resistant version is available as an option for highly filled or abrasive materials; in addition, up to six additives can be controlled with high resolution.