Optical alignment with micrometer precision for overmolding large inserts

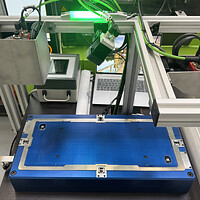

Our newly developed optical alignment system sets a clear benchmark: inserts are positioned consistently and with high precision in the mold – without mechanical centering, solely by means of vacuum and intelligent image processing.

High-performance cameras capture two characteristic component features each, calculate the intersection point, and use this to determine the position with an accuracy of 0.015 mm. A specially developed positioning table then moves the insert to the optimal X/Y position with a resolution of 0.0014 mm and compensates for the angle of rotation so that the transfer inserts the parts precisely into the mold in each cycle (+/- 0.002 mm). All measurement data, paths, and identification codes are stored automatically.

The result speaks for itself: in the first FAT (Factory Acceptance Test), we significantly exceeded the customer's specification of ±0.45 mm – with a maximum variance of only ±0.045 mm.

What does this mean for applications?

• Precise alignment, especially for flat components such as films

• Secure positioning of parts with high thermal expansion without preheating

• New design possibilities for silicone geometries without mechanical centering

• Quality data can be recorded, checked, and logged

• Traceability per component possible (including injection parameters)

• Suitable for manual and fully automated processes

ELMET mold technology ensures that this precision remains stable even in closed, vacuumed tool processes.